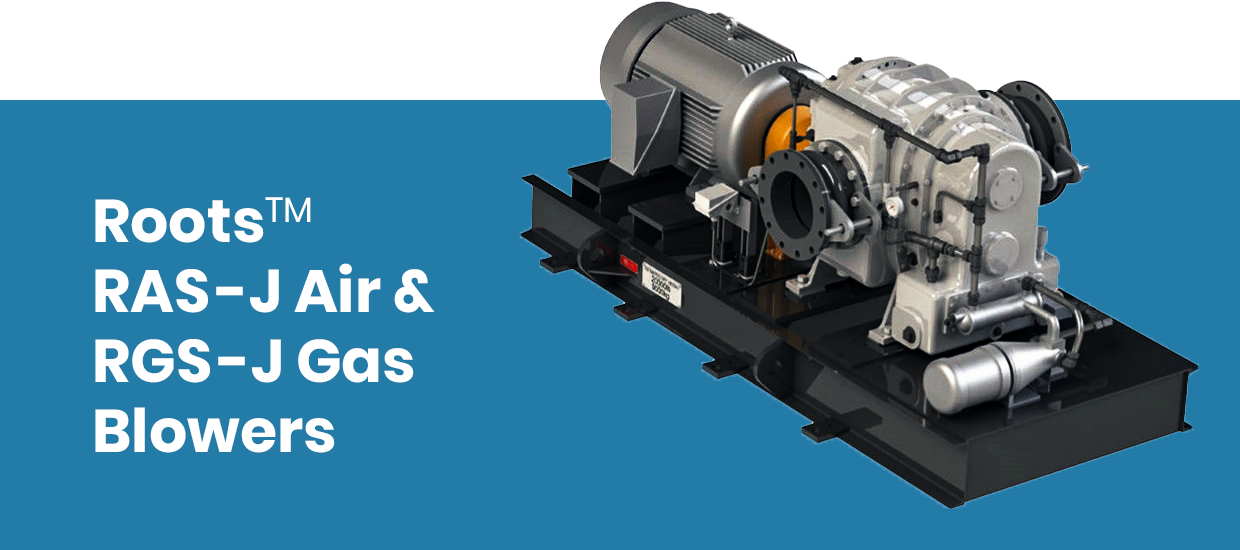

Roots™ RAS-J Air & RGS-J Gas Blowers

The Roots proprietary WHISPAIR* design reduces stress, vibration and noise in your blower and piping system. Conventional blowers produce downstream pressure pulse waves which buffet your air or gas delivery system up to 120 times per second. These pulses and vibrations can steal power and shorten the life of every bearing, gear and other drive train component. WHISPAIR technology reduces the strength of the blower pulse up to 40%, throughout the air/gas delivery system.

WHISPAIR Technology Features

- Lower energy consumption. The patented WHISPAIR jet design precisely meters backflow and channels air pressure in the direction of impeller rotation. The result is an extra “push” that reduces the power required to drive the impellers.

- Longer bearing life. Less pulse transmitted through the impellers means approximately 20% longer bearing life. With less pulse and vibration, other components such as timing gears, drive couplings, v-belts and motor bearings suffer less stress.

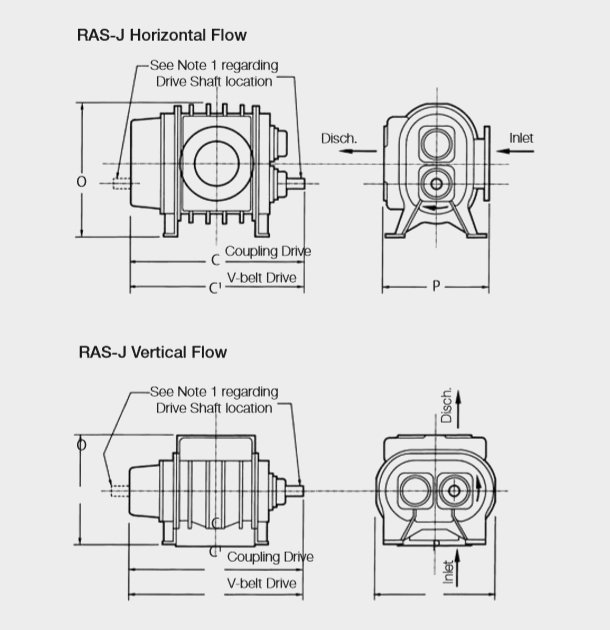

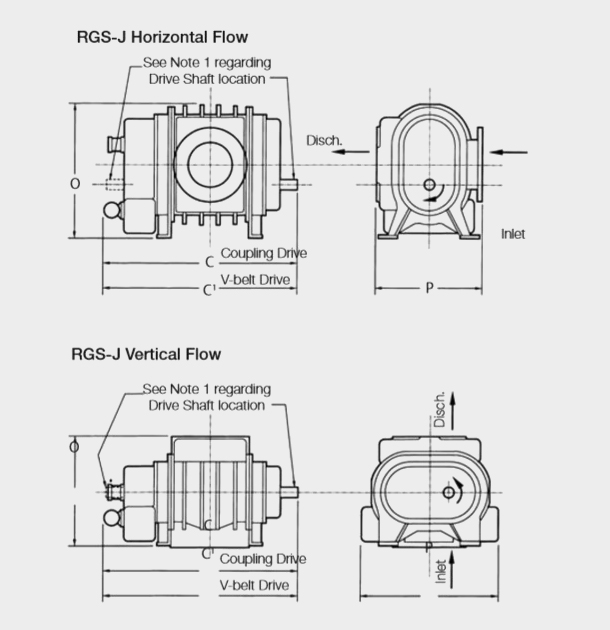

- Cylinder and headplates. All RAS-J and RGS-J blower units are configurable to horizontal or vertical flows. Cylinders and headplates are precision machined grey iron, with cast ribs for improved strength and heat transfer. Castings may be subjected to strenuous pressure and leak testing to help preserve integrity in the most demanding applications. Each RGS-J machine is leaked tested to 1.25 times casing design pressure; optional hydrostatic testing available to 1.5 times casing design pressure.

Roots centrifugal compressors.

High performance and low maintenance.

RAS-J/RGS-J Blowers

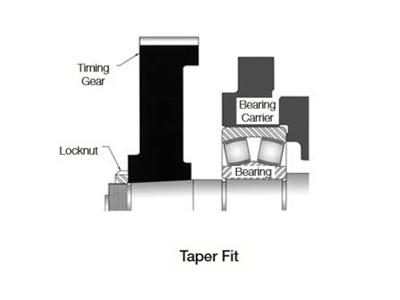

Timing gear locking arrangment for 1000J frame sizes

RAS-J/RGS-J Blowers

Timing gear locking arrangment for 1200J - 2000J frame sizes

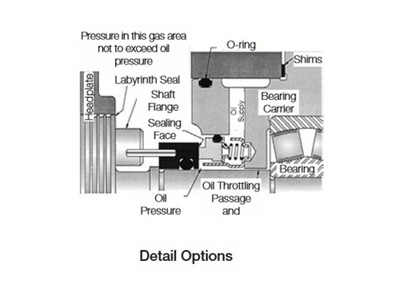

RAS-J Gas Blowers

Detail mechanical seal

RAS-J Air WHISPAIR Blower

RGS-J Gas WHISPAIR Blower

Note 1: Standard drive shaft location is dependent upon frame size: 10xx through 14xx frame sizes - drive shaft is located on the opposite gear end of the machine and is shown in heavy type. 16xx through 20xx frame size - drive shaft is located on the gear end of the machine as shown by dotted lines. For all direct drive applications torsional analysis of the whole drive train is required and in the case of drivers other than electric motors, gear end drive must be specified. Frame sizes 10xx through 14xx can be belt driven with the addition of an optional extra bearing and selection of correct pulley combination.

Each unit tested and certified

Each RAS-J blower and RGS-J gas blower is mechanically tested to ensure that the unit meets performance specifications. Our units are tested to design extremes of speed, pressure and temperature. We validate flow capacity oil circulation, operating clearances and vibration at these critical performance levels. We also offer testing that meets your special process requirements and qualifications.

Each unit tested and certified

Our sales professionals are available around the globe and we offer blower service and repair from facilities in Connersville, Indiana, Houston, Texas, Skelmersdale, United Kingdom, Mexico City, Mexico, Dubai, UAE, and Shanghai, China. A network of authorized Roots blowers and compressors distributors is available around the globe to support your blower requirements. Each distributor facility is equipped and staffed with factory trained service personnel to meet your unique needs. These facilities regularly service unit from many OEMs and keep parts on hand for quick turn-around.